CHOCOLATE EQUIPMENTS

Swamiraj Engineering is a process equipment designer and manufacturer of custom-made equipment as per client requirements in the fields of chemical, pigment, chocolate, food, distillery, and brewery industries. Swamiraj Engineering is well recognized for its high-performance design and engineering along with innovative, cost-effective, and quality products.

List of Process Equipment Supplied To Chocolate Plant

- Chocolate Mixer

- Homogenizer Tank

- Chocolate Storage Tank/ Chocolate Tank

- Sigma Mixer

- 1KL FAT Storage Tank with Jacket and Puff Insulation

- Tipping Station and Vibro Sieve

- Rotary Magnet with quick Clean Mechanism

- Belt Conveyor with Food Grade Belt

- 30KL FAT Tank with Pillow Jacket Laser Welded Tank

- Batching Hopper

- Weigh Silo

- Cooling Table

- Ribbon Blender Jacketed Type

- Rotary Airlock Valve

- Knife Gate Valve (Electro Pneumatic Operated)

- Screw Conveyors

- Inclined Tubular Screw Conveyors

Chocolate Mixer

Swamiraj engineering design and supply chocolate mixers, to mix thick and highly viscous material, generating enough torque to thoroughly mix all the ingredients together into homogeneous chocolate mixture.

Chocolate Tank

We Design and supply Vertical Tank with Agitator and with Laser welded pillow Jacket for Chocolate Storage & mixing. The entire vessel is GMP Finish and as per Sanitary requirements & regulations. The capacity of Tank Varies from 5KL to 20 KL Tanks.

Homogenizer tank is fast and efficient and are capable of producing a fine droplet or particle size, typically in the range of 2 – 5 microns. This degree of homogenization is suitable for the flavour emulsions

Sigma Mixer

Sigma mixers consists of two mixing blades placed in a ‘w’ shaped horizontal trough. The rotation of the blades is either tangential to each other or the blades overlap within the trough. The blades are so designed that the resulting output is homogeneous mixing. The blade profile of the sigma blade is such that the viscous mass of material is sheared, compressed, kneaded and folded by the action of the blades against the trough of the mixer.

Tangential blade is used for material of higher viscosities such as adhesives, dyes and pigments. Capacity Range from 100 Liters to 500 Liters. MOC : SS304 & SS316L

Belt conveyor Food grade Belt

Inclined Chocolate Mass Feeder

30 KL Fat Storage Tank with Pillow Jacket Laser Welded Tank

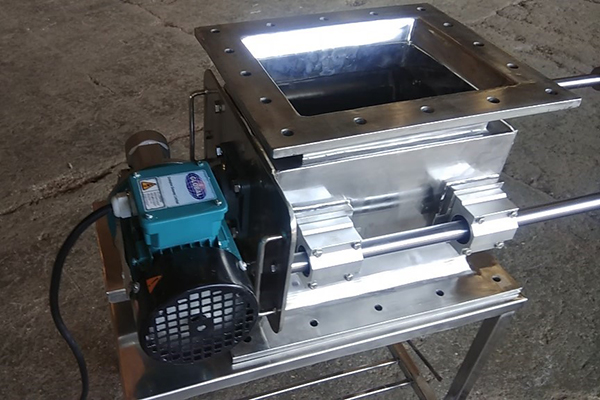

Rotary Magnet Quick Clean Type

Chocolate Storage Tank 1KL with Jacket and Puff Insulation

Chocolate Tank 10KL

Chocolate Storage Tank Agitator Shaft

Homogenizer Shaft 1KL Tank

Features

- Versatile design

- High efficiency

- High performance

- Innovative, flexible, and cost-effective solutions

- Enhanced process control

- Process-specific design

- Highly customizable design

- Manufactured with high-quality stainless steel and carbon steel materials

Applications

- Chemical Industries

- Dyes & Pigment Industries

- Chocolate and Food Industries

- Distillery and beverages

- Cement Plant